Boeing is teamed with Lockheed

Martin, Pratt & Whitney and the U.S. Air Force to develop the F-22 Raptor as a

replacement for the F-15.

The fast, agile, stealthy F-22 will take over the air superiority role with Air

Combat Command starting in 2005. The Air Force plans to procure 339 F-22s, and

production is scheduled to run through 2013.

Mission

The F-22's primary mission is to establish absolute control of the skies over

any battlefield — a must-have in modern warfare. It provides first-look,

first-shot, first-kill capability. The F-22 is an air superiority fighter with

much improved capability over current Air Force aircraft. Its stealth,

supercruise ability, integrated avionics and other features will make it the

most potent fighter in the world.

Current

Activity

A $9.55 billion contract for F-22 Engineering and Manufacturing Development, or

EMD, was awarded to the team in August 1991. Contract changes since then

have elevated the contract value to approximately $15 billion. Under the terms

of the contract, the F-22 team is completing the design of the aircraft and

avionics, building production tooling, and manufacturing and testing nine

flight-test and two ground-test aircraft.

In December

1998, the U.S. Air Force exercised a firm fixed-price contract option with

the Lockheed Martin/Boeing contractor team totaling approximately $189 million

for advance procurement of six Low Rate Initial Production aircraft.

The production

option was exercised less than a week after the Air Force exercised firm

fixed-price contract options totaling approximately $503 million for two F-22

production representative test vehicle aircraft and associated program support

for calendar year 1999.

In December

1999, the F-22 team was awarded contracts totaling more than $1.5 billion to

build six additional production representative test vehicle. Aircraft deliveries

are scheduled to begin in November 2001 and continue through December 2002.

Raptor

Unveiled, Flight Testing Begins

The first F-22 built under the EMD contract was unveiled in a ceremony on April 9, 1997,

in Marietta, Ga. First flight took place on Sept. 7, 1997, and in

May 1998, Raptor 01 made its formal entry into flight test. The newest

F-22, Raptor 03, made its first flight in March 2000 with Boeing pilot

Chuck Killberg at the controls.

Significant

flight milestones that have been met include surpassing the Congressionally

mandated 183 flight-test hours, supersonic flight, in-flight refueling, weapon

release and completing ground-vibration tests and angle-of-attack tests.

As of April 2000,

F-22 pilots at the Combined Test Force, Edwards Air Force

Base, Calif., have logged 618 hours and 272 flights in the program's

three test F-22s.

Avionics

Integration

Boeing, responsible for integrating the Raptor's advanced avionics, has been

testing software "blocks" in both its avionics integration lab, or

AIL, since 1998, and on its 757 Flying Test Bed, or FTB, since March 1999. Both

the AIL and FTB are helping reduce avionics risks and development costs by

enabling extensive evaluation and troubleshooting before full avionics are ever

installed on the F-22.

As of April 2000,

Boeing has completed more than 15,000 hours of avionics testing in the AIL and

430 hours on the FTB. Boeing delivered the first avionics flight-test package,

Block 1.1, to Lockheed Martin ahead of schedule in May 1999. Boeing now is

testing an early version of Block 3.0 software on the FTB.

F-22 Team

The F-22 teaming arrangement has allowed unprecedented industry cost-sharing and

taken advantage of the different companies' strengths in advanced technology,

production capability and systems integration.

Prior to its

selection as winner of what was then known as the Advanced Tactical Fighter

competition, the F-22 team conducted a 54-month demonstration/validation

program. The effort involved the design, construction and flight testing of two

YF-22 prototype aircraft. Two prototype engines, the Pratt & Whitney YF119

and General Electric YF120, also were developed and tested during the program.

The demonstration/validation program was completed in December 1990.

Much of that

work was performed by Boeing in Seattle, Wash.; Lockheed (now Lockheed Martin)

in Burbank, Calif.; and General Dynamics (now Lockheed Martin) in Fort Worth,

Texas. The prototypes were assembled in Lockheed's Palmdale, Calif., facility

and made their maiden flights from there. Since that time Lockheed's program

management and aircraft assembly operations have moved to Marietta, Ga.,

for the EMD and production phases.

Division of

Work

Boeing in Seattle, Wash., is responsible for the wings, aft fuselage

(including the structures necessary for engine and nozzle installation),

avionics integration, 70 percent of mission software, the training system,

flight-test development and management, and the training, life-support and

fire-protection systems.

Lockheed Martin

Aeronautical Systems, a division of Lockheed Martin Corporation, based in

Marietta, Ga., is responsible for program management, the integrated

forebody (nose section) and forward fuselage (including the cockpit and inlets),

leading edges of the wings, the fins and stabilators, flaps, ailerons, landing

gear and final assembly of the aircraft.

Lockheed Martin

Tactical Aircraft Systems, based in Fort Worth, Texas, is responsible for the

center fuselage; stores management; integrated navigation and electronic warfare

systems; the communications, navigation, and identification system; and the

weapon support system.

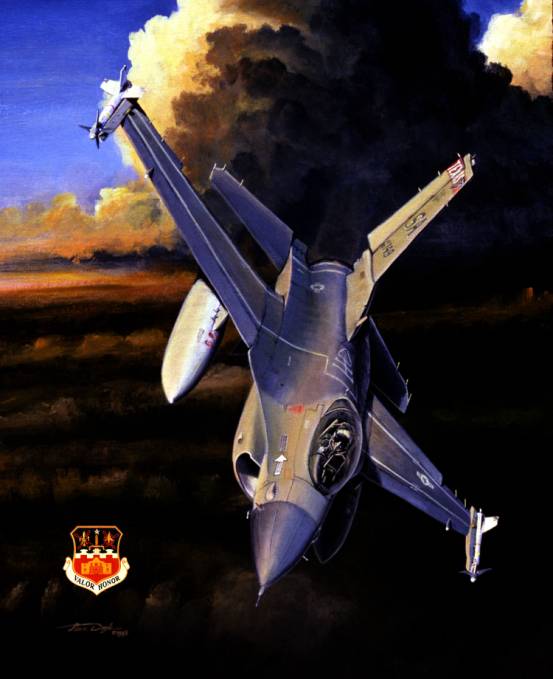

The F-16 Fighting Falcon is a compact, multirole fighter aircraft. It is

highly maneuverable and has proven itself in air-to-air combat and

air-to-surface attack. It provides a relatively low-cost, high-performance

weapon system for the United States and allied nations.

In an air combat role, the F-16's maneuverability and combat radius

(distance it can fly to enter air combat, stay, fight and return) exceed that of

all potential threat fighter aircraft. It can locate targets in all weather

conditions and detect low flying aircraft in radar ground clutter. In an

air-to-surface role, the F-16 can fly more than 500 miles (860 kilometers),

deliver its weapons with superior accuracy, defend itself against enemy

aircraft, and return to its starting point. An all-weather capability allows it

to accurately deliver ordnance during non-visual bombing conditions.

In designing the F-16, advanced aerospace science and proven reliable

systems from other aircraft such as the F-15 and F-111 were selected. These were

combined to simplify the airplane and reduce its size, purchase price,

maintenance costs and weight. The light weight of the fuselage is achieved

without reducing its strength. With a full load of internal fuel, the F-16 can

withstand up to nine G's -- nine times the force of gravity -- which exceeds the

capability of other current fighter aircraft.

The cockpit and its bubble canopy give the pilot unobstructed forward and

upward vision, and greatly improved vision over the side and to the rear. The

seat-back angle was expanded from the usual 13 degrees to 30 degrees, increasing

pilot comfort and gravity force tolerance. The pilot has excellent flight

control of the F-16 through its "fly-by-wire" system. Electrical wires

relay commands, replacing the usual cables and linkage controls. For easy and

accurate control of the aircraft during high G-force combat maneuvers, a side

stick controller is used instead of the conventional center-mounted stick. Hand

pressure on the side stick controller sends electrical signals to actuators of

flight control surfaces such as ailerons and rudder.

Avionics systems include a highly accurate inertial navigation system in

which a computer provides steering information to the pilot. The plane has UHF

and VHF radios plus an instrument landing system. It also has a warning system

and modular countermeasure pods to be used against airborne or surface

electronic threats. The fuselage has space for additional avionics systems.

The F-16A, a single-seat model, first flew in December 1976. The first

operational F-16A was delivered in January 1979 to the 388th Tactical Fighter

Wing at Hill Air Force Base, Utah.

The F-16B, a two-seat model, has tandem cockpits that are about the same

size as the one in the A model. Its bubble canopy extends to cover the second

cockpit. To make room for the second cockpit, the forward fuselage fuel tank and

avionics growth space were reduced. During training, the forward cockpit is used

by a student pilot with an instructor pilot in the rear cockpit.

All F-16s delivered since November 1981 have built-in structural and

wiring provisions and systems architecture that permit expansion of the

multirole flexibility to perform precision strike, night attack and

beyond-visual-range interception missions. This improvement program led to the

F-16C and F-16D aircraft, which are the single- and two-place counterparts to

the F-16A/B, and incorporate the latest cockpit control and display technology.

All active units and many Air National Guard and Air Force Reserve units have

converted to the F-16C/D.

The F-16 is being built under an unusual agreement creating a consortium

between the United States and four NATO countries: Belgium, Denmark, the

Netherlands and Norway. These countries jointly produced with the United States

an initial 348 F-16s for their air forces. Final airframe assembly lines were

located in Belgium and the Netherlands. The consortium's F-16s are assembled

from components manufactured in all five countries. Belgium also provides final

assembly of the F100 engine used in the European F-16s. The long-term benefits

of this program will be technology transfer among the nations producing the

F-16, and a common-use aircraft for NATO nations. This program increases the

supply and availability of repair parts in Europe and improves the F-16's combat

readiness.

USAF F-16 multi-mission fighters were deployed to the Persian Gulf in

1991 in support of Operation Desert Storm, where more sorties were flown than

with any other aircraft. These fighters were used to attack airfields, military

production facilities, Scud missiles sites and a variety of other targets.

Primary

Function: Multirole

fighter

Builder:

Lockheed Martin Corp.

Power

Plant: F-16C/D: one

Pratt and Whitney F100-PW-200/220/229 or General Electric F110-GE-100/129

Thrust:

F-16C/D, 27,000 pounds(12,150 kilograms)

Length:

49 feet, 5 inches (14.8 meters)

Height:

16 feet (4.8 meters)

Wingspan:

32 feet, 8 inches (9.8

meters)

Speed:

1,500 mph (Mach 2 at altitude)

Ceiling:

Above 50,000 feet (15

kilometers)

Maximum

Takeoff Weight: 37,500

pounds (16,875 kilograms)

Range:

More than 2,000 miles ferry range (1,740 nautical miles)

Armament:

One M-61A1 20mm

multibarrel cannon with 500 rounds; external stations can carry up to six

air-to-air missiles, conventional air-to-air and air-to-surface munitions and

electronic countermeasure pods.

Unit

cost: F-16C/D, $20

million plus

Crew:

F-16C: one; F-16D: one or two

Date

Deployed: January 1979

Inventory:

Active force, 444; Air

National Guard, 305; Reserve, 60.

Point

of Contact